Polished Concrete

KC Concrete Flooring Restoration provides protection to your concrete flooring investments

Write your caption hereButton

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

List of Services

-

Cost SavingsList Item 1

Polished concrete is extremely inexpensive! The high cost of traditional flooring materials such as carpet, tile, VCT and laminate aren't necessary when the original slab is going to be used as the finished floor surface.

-

Resilient in High Traffic AreasItem Link

Unlike other flooring materials, polished concrete floors will never fade. Even if stained, the stain will not faid under the heaviest of traffic.

-

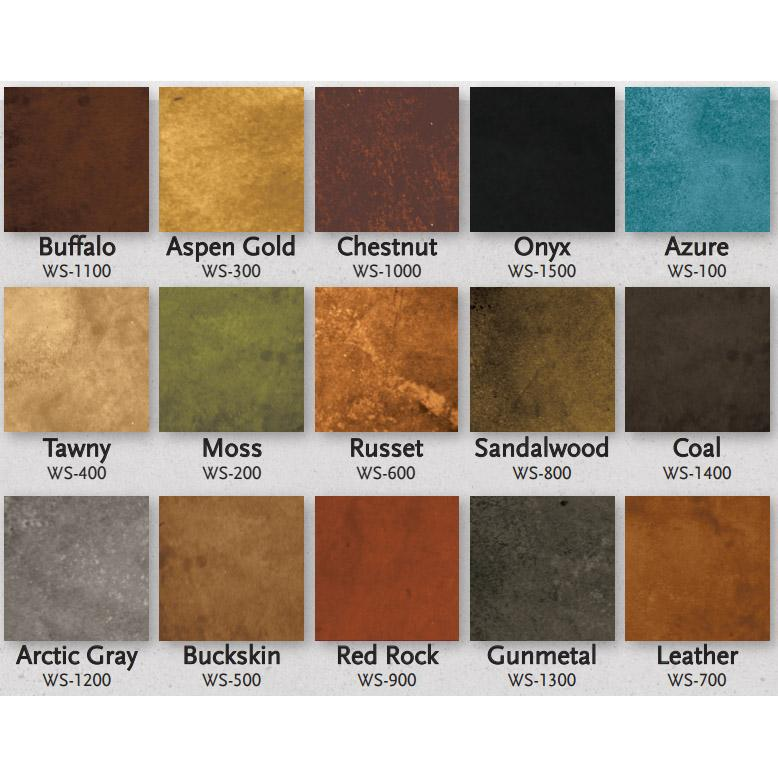

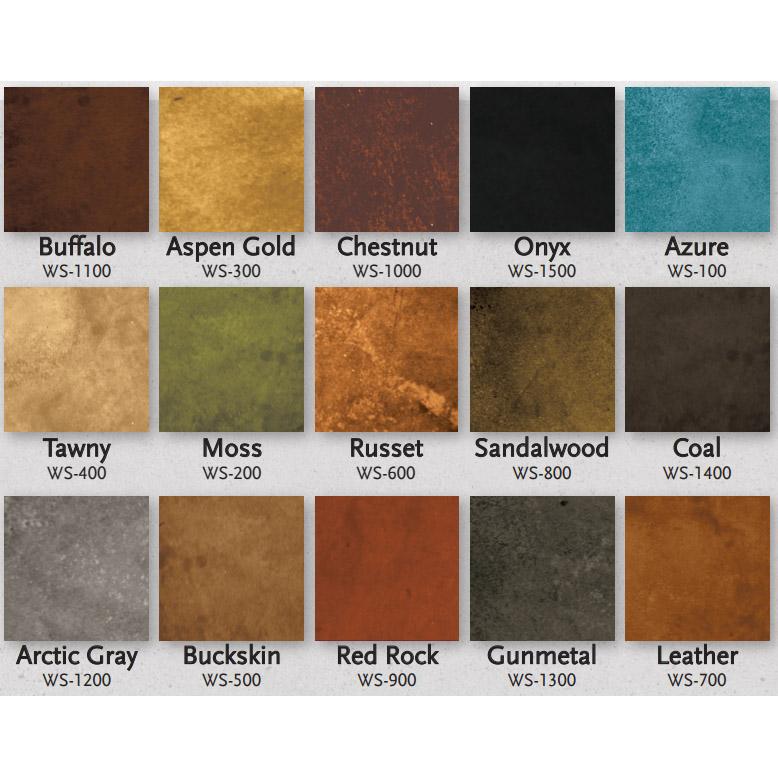

Colors & DesignsItem Link List Item 3

Concrete can be easily stained to match any existing decor and the color possibilities for your floors are endless. From simple colors to detailed borders, logos and designs, your concrete floors are only limited by imagination.

-

Less MaintenanceItem Link

Polished concrete floors are not only easy to clean, they usualy require only the occasional damp mopping. No wax is necessary in order to maintain the shine of your new floor! Polished concrete floors eliminate the need for additional protectants as well as the labor, time and expense to apply them.

List of Services

-

Resistant to Moisture ProblemsItem Link List Item 1

Polished concrete floors, unlike some epoxy, laminate and wood floors, alllows the floor to appropirately breathe and eliminates all the issues that may arise with other flooring materials that completely seal the concrete.

-

ReflectivityItem Link List Item 2

This is very important for places like warehouses, office buildings, hotel floors, restaurant floors, and other public places that would like to project a brighter, cleaner, more professional image. Polished concrete floors can also save energy by reducing the amount of artificial lighting required.

-

Sustainable Flooring AlternativeItem Link List Item 3

Polished concrete doesn't need any type of hazardous coatings or cleaners. Environmentally friendly flooring that's easy on your budget!

-

VersatileItem Link List Item 4

Because polishing concrete is a step-by step process, busines owners and homeowners alika are able to choose amount of shine and design to fit their maintenance and aesthetic requirements. The versatility makes our concrete floors an excellent flooring option for a variety of places.

Concrete Polishing Process

Cleaning the Surface

Shot blasting is the number one method of floor preparation for epoxy and waterproofing applications. It is a mechanical process of profiling concrete in order to remove contaminants and open the pores allowing for better adhesion.

This process is much more environmentally friendly than other floor prep processes such as chemical treatments. State of the art vacuum systems are connected to all of our shot blasting machines to limit dust and debris at your job site.The first step in the process is aggressively grinding the concrete to remove any old paint, glue, thinset, or any other superficial contaminant or stain.

Diamond Grinding

Diamond grinding is a method of floor preparation used to remove coatings, and adhesives. Diamond grinding also prepares concrete for architectural staining, and thin mil epoxies. We have a variety of grinders available to tackle your job, whether you have a large industrial building or a small office space. The grinder removes most concrete imperfections and smoothes inconsistent texture. State of the art vacuum systems are connected to all of our grinders to limit dust and debris at your job site.

Have your concrete floors dulled and lost that clean fresh look because of dirt, algae and other unsightly contaminants? KC Concrete Flooring Restoration will remove those contaminants and polish your concrete for a fresh, clean look. Concrete surfaces can be treated with sealers that will further protect them for years to come.

Polishing, Sealing & Burnishing

The following steps include grinding the concrete floors with resin-bonded diamonds to bring the floors to a polish. At some point in this step the stain is applied to the floors if desired, and the concrete is densified to harden it and leave it ready for the full polish.

The final step is to bring the concrete to the desired level of shine, which could be matte, satin, or highly polished. After this, the floors are sealed with an impregnating sealer and burnished twice.